The project

A bio-based material made from cork stopper’s leftovers.

THE CHALLENGE

3D printing is a growing industry, but as a disruptive and innovative technology, the range of materials that can be used is still limited, particularly as regards natural materials. On the other hand, cork is a CO2 sink tree, and its bark, extracted from the cork oak, has great properties.

It absorbs polluting gases and cleans the air, so that, it produces is famous”skin”. The challenge resides in using the powder waste from the cork industry with 3D printing to provide a much greener alternative material.

THE SOLUTION

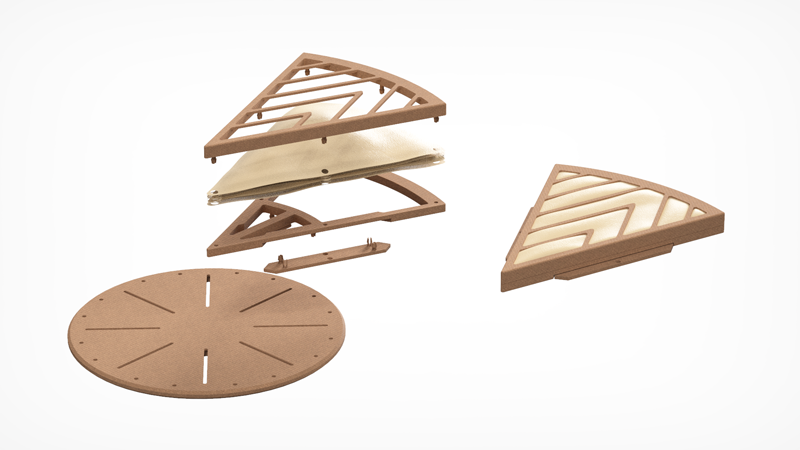

The objective of this project is to create filaments for 3D printers generating a resin to print objects using cork dust, with enhanced thermal qualities and lighter in weight. The idea is to create objects such as lightweight modular coustic panels, lamps, and vases that have sound-absorbing properties thanks to the cork particles and added materials like cork skin and Sardinian sheep wool, therefore using locally-produced waste.

The project is a combination of heritage, exquisite craftmanship and technology, matching the expertise of the Sardinian artisans with cutting edge technology to provide a more sustainable design system.

Storytelling

THE IDEA:

I come from a small town in the heart of Sardinia island, a town that managed to survive from its origins until today thanks to the extraction and processing of cork, an abundant resource on the island, due to the Mediterranean climate and the cleanliness of the air, which allows a perfect development of the cork oak skin. My grandfather was the founder of a small family business that nowadays continues to produce cork caps as it was done 70 years ago. When I was a child, in summer, I had to help my grandfather cleaning the factory, and I was always interested in the big sacks of cork particles that were storaged and burned without any other utility. Starting there, I came across with the idea of using the waste produced from the filling of the cork stoppers, as a resource to develop a circular and sustainable production system creating a new bio-based materials with less environmental impact, since that cork waste has been already produced and thus we keep the CO2 in the material without releasing it into the atmosphere during the combustion.

THE BIRTH OF THE PROJECT:

The aim is to create a 3D cork filament with a higher % of biobased content and biodegradable for Interior Design uses. Worth Project is an occasion to show one of the many application of this material for interior design: sound absorbing panels made out cork, recycled hemp and compostable polymers. The demand for eco-friendly or bio-based products has increased due to the implementation of stringent environmental regulations and the growing preference for environment-friendly products. Recycling and reuse of cork waste also help end-users comply with sustainable manufacturing policies and reduce pollution. This will compel vendors to adopt sustainable manufacturing processes, which will support the growth of bio-based products. Design and Fashion brands are now at a pivotal point. They need to innovate and invest in products and processes that embrace sustainability, but it is very difficult to change mass production without R&D in a short time. Lebiu provides eco-materials for this production transformation.

THE CREATIVE PROCESS:

The concept ideation and the design derived from it are part of a very interesting and enriching process, involving the mentors and people from different fields who came together in creating innovative products. Some problems came out when testing the compound and creating the recipe, the delays due to the pandemic situation and the lack of a dynamic communications between Lebiu and the factory created difficulties in implementing the project.

THE COLLABORATION:

Partnering with FabLab Venezia has been very fruitful and it’s a pleasure to work with them. They have a responsible team and are open to help you in technical/ operational issues. Working as a team fills the gaps that each partner has in a complementary way. Also, it helps you to have a different point of view, receiving constant feedback during the entire process.

THE FUTURE:

The goal is to go on the market by the end of 2021 with the cork filament. Before that, a marketing campaign will be held by Lebiu to promote the applications of the filament presenting the sound absorbing panels in design contest, art and design shop and online. Currently, we are looking for compound and extruders providers to produce the filament and finally sell it on multichannel platform and private.

THE MESSAGE:

The partnership is a win-win collaboration where Technology and Crafting merge together creating a new product system. So I highly encourage designers to focus on new production cycles to generate a new eco-consciousness and change the actual production model into a more sustainable and ethical system.

- Project locations

- SpainItaly

- Project website

- lebiudesign.com

- Projects Edition

- WORTH Partnership Projects I

- Project Call

- 3rd Call Projects

- Project Sector

- Furniture, home decoration, interior design and architecture

- Project Challenge

- Reinventing craftsmanship

Contact

FABIO MOLINAS

FABLAB VENEZIA

Fablab Venezia is a digital fabrication lab, born in 2014 with the aim of helping enterprises, designers, artisans, and creative people develop their ideas and innovative projects using digital technologies such as 3D Printing, CNC Milling and Robotics.

- Name

- FABLAB VENEZIA

- Postal address

Italy

- Social media